RISE DEFENSE SYSTEMS.AI PRODUCTS

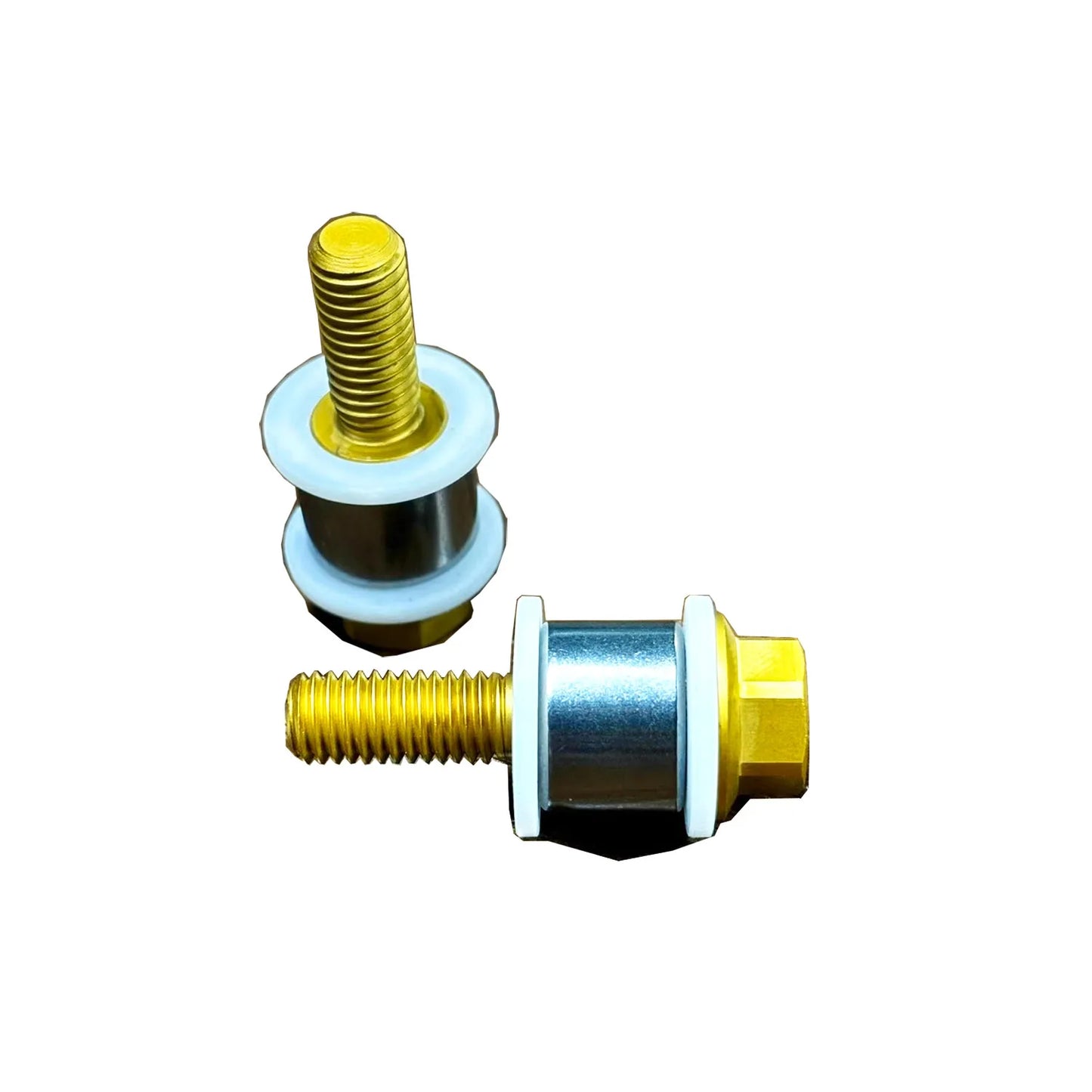

Upper turning point oiling bolt SURRON Light bee S/X rear shock linkage linkage needle bearing kit LB upgrade bearing kit

Upper turning point oiling bolt SURRON Light bee S/X rear shock linkage linkage needle bearing kit LB upgrade bearing kit

Couldn't load pickup availability

SPECIFICATIONS

Brand Name: NoEnName_Null

Origin: Mainland China

Hign-concerned Chemical: None

Use: Mountain Bikes

Material: ALLOY

Model Number: LBXMOD

SURRON Light S/X Rear Linkage Mounting Bolt Oilable Bolt

Rack Mounting Bolt Oiler Bolt for upper swivel point. High-quality chrome steel with 12.9 grade heat treatment and titanium plating, effectively preventing needle bearings from rusting in water. Installation torque 10NM, hit thread glue. Lock too tightly will compress the end face of the triangle connecting rod causing collapse and make the triangle connecting rod rotate heavier. Nylon shims and needle bearings are supplied with the kit.

Hello, everyone, today I would like to introduce you to a Light bee Ebike frame on the turn point oiling bolt, Light bee frame needle bearings are very easy to enter the water rust. This is very common in maintenance cases, Light bee's two needle bearings are not waterproof, it can only through the two sides of the Teflon spacer, play a closed role, to achieve a slight dust effect, after a long time, it is very easy to enter the water damage. In order to enhance the waterproof bearing, we can inject a large amount of grease into the middle of the bearing, but it original screws will extrude the grease outward during the installation process, and with the passage of time, the grease will also be overflowed outward, and then lose the waterproof property.

Then the function of our oiling bolt is to inject a large amount of solid water grease into the bearing directly through the oiling port without disassembling and maintenance, which also plays the effect of waterproof, dustproof and rustproof. Let's take a look at its oiling effect, this is what it looks like after the oiling bolt is installed. Now we'll just inject grease directly into the back of the bearing for water resistance. You can see there's already oil spilling out here, OK take another look. The other side of this top tighten you see the grease from this out, the back has been back has come out, you can see the effect is still very good. Bolt installation is complete. Then later in each car wash or after heavy use, no longer need to frequent disassembly, only need to inject grease into the hole, you can achieve the purpose of maintenance.

Share